- Exhaust Insulation

- A comparison of the types of exhaust insulation

- What is the best insulation for exhaust surfaces?

- Why do diesel exhaust aftertreatment systems have so many components?

- What do each of the components of a diesel exhaust aftertreatment system do?

- What is regeneration (regen)?

- What is back pressure?

- What is the difference between various engine tiers?

- What is the difference between Tier 4i and Tier 4f?

- Will aftermarket exhaust parts fit my machine?

- The DPF and You

- Equipment & Emissions

- How Mammoth Can Help

Equipment & Emissions

6.3.2.1 Standard Method

All diesel particulate testing shall be carried out using the following method unless the diesel engine cannot be held in the load condition for 20 seconds in which case testing shall be carried out in accordance with clause 6.3.2.2 below.

a) Testing equipment shall comply with clause 8.2 Diesel Particulate Monitoring Equipment. Note: It is not possible to use the Bosch Smoke Meter for the above tests due to its inability to measure over a 60 second sampling period.

b) Exhaust sampling and analysis shall be carried out by a person competent to the satisfaction of the mine mechanical engineer to carry out such test or by a licensed laboratory.

c) The diesel engine shall be operated until the engine temperature stabilizes. Exhaust particulate sampling and analysis shall be performed when the diesel engine is at normal operating temperature.

d) The vehicle must be safely chocked and the vehicle brakes must be applied. Important Safety Notice. As engines must be tested in the load condition requiring the drive train to be engaged during testing it is important the vehicle is adequately chocked or restrained and the brakes applied to ensure it cannot “jump” or run away while the diesel engine is under throttle during the test.

e) Place vehicle in third gear or other gear as specified by the equipment manufacturer to carry out the test.

f) Run the engine at idle speed.

g) Insert sensor probe into the undiluted raw exhaust before any particulate treatment. Note: This may be downstream of catalytic converters and water based scrubbers but must be before any particulate filter.

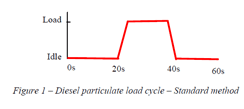

h) Testing shall be carried out over a 60 second cycle and on the undiluted raw exhaust as indicated in Figure 1 below. Notes:

- It is important that the timing of the idle and full throttle settings is as accurate as possible. To ensure good repeatability, it is advisable for the operator to practice the procedure several times prior to collecting a sample.

- Sampling should commence in the first idle period and continue until the final idle period.

- Engines with a constant load, such as a diesel should be analyzed with the load applied over the full 60 seconds.

i) Start sampling timer on analyzer.

j) After 20 seconds have an operator quickly apply full throttle to engine (still in third gear) and hold for 20 seconds.

k) Quickly release throttle and allow engine to decay to idle while sampling for 20 seconds.

l) Stop sampling timer on analyser.

m) The total sampling time is 60 seconds. The sampling must pick up rise and decay of the engine from idle to full throttle and return to idle.

n) Remove the probe if no further testing is required.

o) Record the mean (average) engine exhaust diesel particulate concentration in (mg/m3).

6.3.2.2 Standard Method

Where testing in accordance with clause 6.3.2.1 above is not practicable (such as engines fitted with manual clutches) diesel particulate testing of the undiluted raw exhaust of diesel engines shall be carried out as follows:

a) Testing equipment shall comply with clause 8.2 Diesel Particulate Monitoring Equipment. Note: It is not possible to use the Bosch Smoke Meter for the above tests due to its inability to measure over a 60 second sampling period.

b) Exhaust sampling and analysis shall be carried out by a person competent to the satisfaction of the mine mechanical engineer to carry out such test or by a licensed laboratory.

c) The diesel engine shall be operated until the engine temperature stabilises. Exhaust particulate sampling and analysis shall be performed when the diesel engine is at normal operating temperature.

d) The vehicle brakes must be applied. Important Safety Notice It is important the vehicle is adequately chocked or restrained and the brakes applied to ensure it cannot “jump” or run away in the event the gear control lever is accidentally engaged while carrying out the test.

e) Place vehicle in neutral to carry out the test. Ensure the transmission is not engaged.

f) Run the engine at idle speed.

g) Insert sensor probe into the undiluted raw exhaust before any particulate treatment. Note: This may be downstream of catalytic converters and water based scrubbers but must be before any particulate filter.

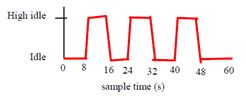

h) Testing shall be carried out over a 60 second cycle and on the undiluted raw exhaust as indicated in Figure 2 below. Notes:

- It is important that the timing of the idle and full throttle settings is as accurate as possible. To ensure good repeatability it is advisable for the operator to practice the procedure several times prior to collecting a sample.

- Sampling should commence in the first idle period and continue until the final idle period.

- During the acceleration stages of these tests a full fuel load is being delivered to the engine until it is near its governed speed.

i) Start sampling timer on analyzer.

j) Continue to idle until timer indicates 8 seconds.

k) Have an operator quickly apply full throttle, hold until timer indicates 16 seconds and quickly release throttle.

l) Idle engine until timer indicates 24 seconds.

m) Quickly apply full throttle again, hold until timer indicates 32 seconds and quickly release throttle.

n) Idle engine until timer indicates 40 seconds.

o) Quickly apply full throttle again, hold until timer indicates 48 seconds and quickly release throttle.

p) Idle engine until timer indicates 60 seconds then stop sampling timer on analyzer.

q) The total sampling time is 60 seconds. The sampling must pick up rise and decay of the engine from idle to full throttle and return to idle for each cycle.

r) Remove the probe if no further testing is required.

s) Record the mean (average) engine exhaust diesel particulate concentration in (mg/m3).

The worker exceedance level for DPM (Diesel Particulate Matter) in ambient air underground varies quite a bit from jurisdiction to jurisdiction. Ambient air exceedance levels are not to be mixed up with undiluted raw exhaust levels found at the tailpipe.. There is no known requirement for tailpipe DPM levels as far as I am aware. Some of the exceedance levels in ambient air conditions in various jurisdictions are as follows (all are a TWA - Time Weighted Average):

- Quebec - 0.4mg/m3

- Ontario - 0.4mg/m3 currently (possibly changing to 0.12mg/m3)

- Saskatchewan - 0.16mg/m3

- USA / MSHA - 0.16mg/m3

- Australia

- 0.1mg/m3 (EC - elemental carbon only)

While many jurisdictions do not have any specific limits around raw undiluted tailpipe Carbon Monoxide limits. Those that do are in the

600 - 750ppm range. This is still quite high as the majority of diesel engines of Tier 1, 2, 3 and 4 emissions level can easily achieve CO levels of less than 100ppm providing their catalyst (also known as a scrubber, purifier or PTX) is working correctly. Many sites would have their own policies and requirements to change the catalyst if they notice the CO level start to climb to 200 - 300ppm.

We should draw a clear distinction between ambient conditions exposure limits and undiluted exhaust limits at the tailpipe. Jurisdictions across Canada vary for exposure limits to NO2 as a time weighted average (TWA) from 1ppm in some areas up to 3ppm in other areas. In order to meet these requirements some regions are now introducing tailpipe limits recognizing that by monitoring the tailpipe emissions of each engine contributes to the overall ambient condition in the mine. Jurisdictions that are introducing tailpipe limits all seem to be aiming for the 50-60ppm range for maximum NO2 levels in undiluted exhaust.