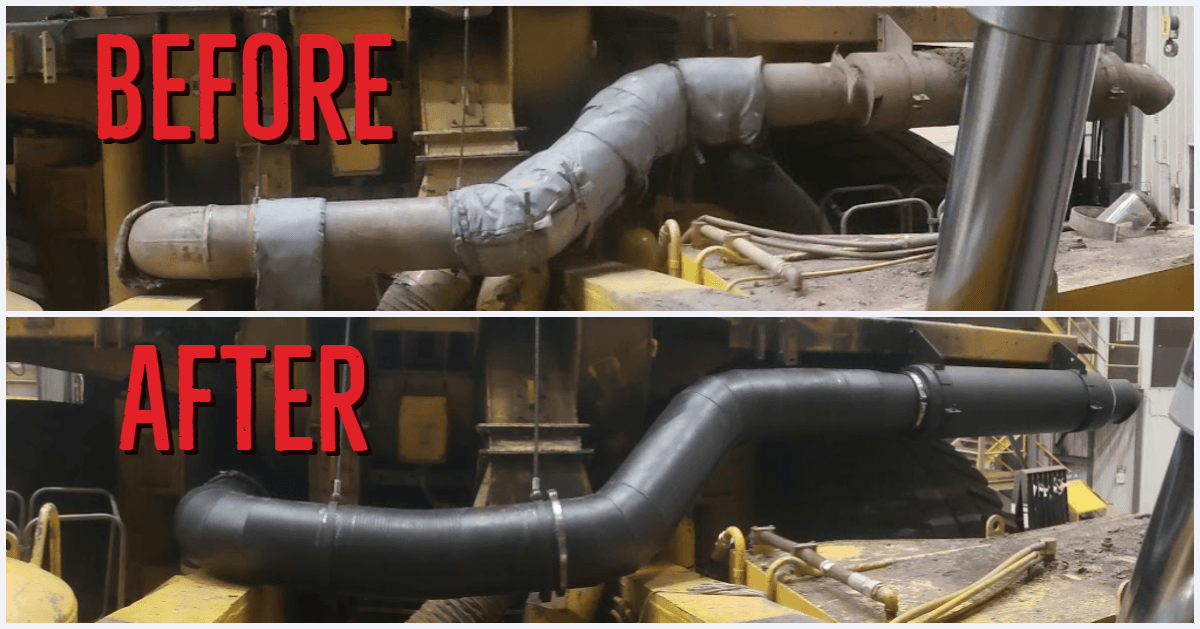

DUAL WALL EXHAUST SYSTEMS

AFTERMARKET EHXUAST SYSTEMS - NO EQUIPMENT MODIFICATIONS REQUIRED

Mammoth Equipment & Exhausts dual walled pipe provides maximum safety and protection from exhaust gas heat being radiated to the surrounding area and your people.

Dual walled pipe is made with two layers of steel pipe which are insulated.

Dual wall pipe which is sometimes referred to as double wall pipe, may be used in conjunction with emissions reduction systems such as DPFs, SCRs or DOCs as they often rely on high exhaust temperatures, achievable through efficient thermal insulation for optimum performance.

BENEFITS OF DUAL WALL EXHAUST

Quality & Durability

Durable exhaust steel impervious to fuels and oils. Resistant to impact damage.

Innovation

Can be water blasted as often as necessary without fear of damaging outer skin.

Safety In Design

Inner insulating material layer proven to reduce touch surface temperature up to 70%

Cost Savings

Our dual wall exhaust kits are an alternative to OEM products and cuts costs up to 40%

Fast Turnaround

With manufacturing facilities globally, it allows us to offer our customers quick fulfillment of orders.

Technical Support

At Mammoth, we offer onsite technical support with our products. Give us a call!

LONGEVITY OF DUAL WALL EXHAUST SYSTEMS

Mammoth insulated pipes are designed as a complete ‘bolt on’ kit. Insulated pipes also ensure fitters and maintenance personnel can work in the engine bay around the pipe without the irritation of insulation fibers.

Dual wall exhaust systems are designed in house and manufactured to the highest standards.

INDEPENDENT TESTS SHOW A 60% REDUCTION IN SURFACE TEMPERATURE

Comparing single walled standard pipe against double walled insulated pipe (Komatsu 830E with a Komatsu SDA16V160 Engine)