DIESEL PARTICULATE FILTERS

Improve air quality for your workers and replace your factory muffler.

NO MODIFICATIONS REQUIRED

Learn how DPF's work

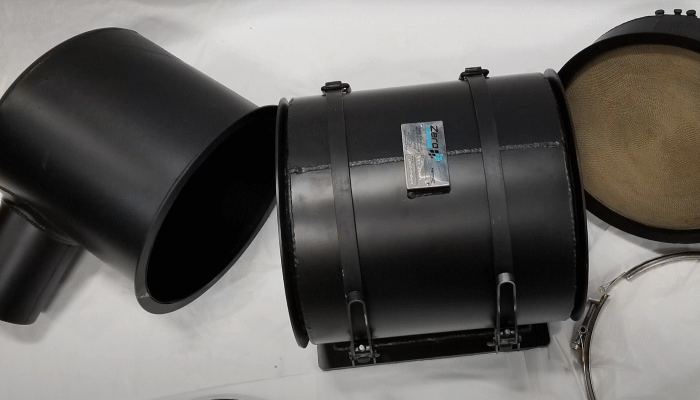

STANDARD DIESEL PARTICULATE FILTER

All of Mammoth’s Diesel Particulate Filters Are purpose built for application, engine type, back pressure specifications and deliver >98% reductions in Diesel Particulate Matter consistently Using robust and durable recrystallized silicone carbide (SIC), known for its Mohs hardness rating close to diamond (9) and a very low thermal expansion coefficient (4.0 × 10−6/K) the Mammoth Diesel Particulate Filter is built stronger, enabling high soot loading and thermal capacity. This passive regenerating monolith is further enabled by the Diesel Oxidation Catalyst module before the substrate ensuring the atmosphere within the filter is optimized for passive regeneration, high performance and reliability.

CATALYZED SUBSTRATE DIESEL PARTICULATE FILTER

Compact Catalysed Diesel Particulate Filters provide highly efficient removal of diesel particulate matter. The key difference is the Diesel Oxidation Catalyst or Precious Metal catalytic coating being integrated onto the substrate face (as opposed to being a separate module upstream from the substrate (saving up to 30% of space) without any sacrifice of results. The catalytic coating oxides harmful exhaust gas such as Carbon Monoxide (CO) and Nitrous Oxides (NOx) as well as Hydrocarbons. The porous channels within the silicone carbide substrate trap soot particles as low as 10um and regenerates in the presence of NOx at an improved ratio due to the compact design.

SINTERED METAL FILTERS

SMF Partial flow Diesel Particulate Filters provide effective removal of diesel particulate matter with lower maintenance requirements than wall-flow particulate filters. Making them the ideal choice for managing diesel particulate emissions on light duty cycle vehicles. SMFs are functionally similar to the standard Diesel Particulate Filter; hot gas (including DPM flows into the filter structure, where the microscopic metallic pores trap and oxidise DPM. The key difference is the sintered metal substrate, which when coupled with the Diesel Oxidation Catalyst enables soot oxidation at lower temperatures and partial flow, virtually eliminating the risk of over-sooting; maintenance and manual regeneration not required

ADVANTAGES OF ZERO DIESEL PARTICULATE FILTERS

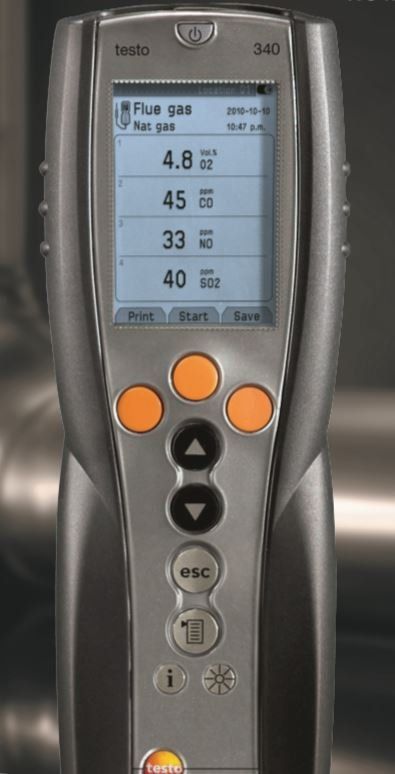

INLET & OUTLET AFTER 20 MINS UNDER FULL LOAD

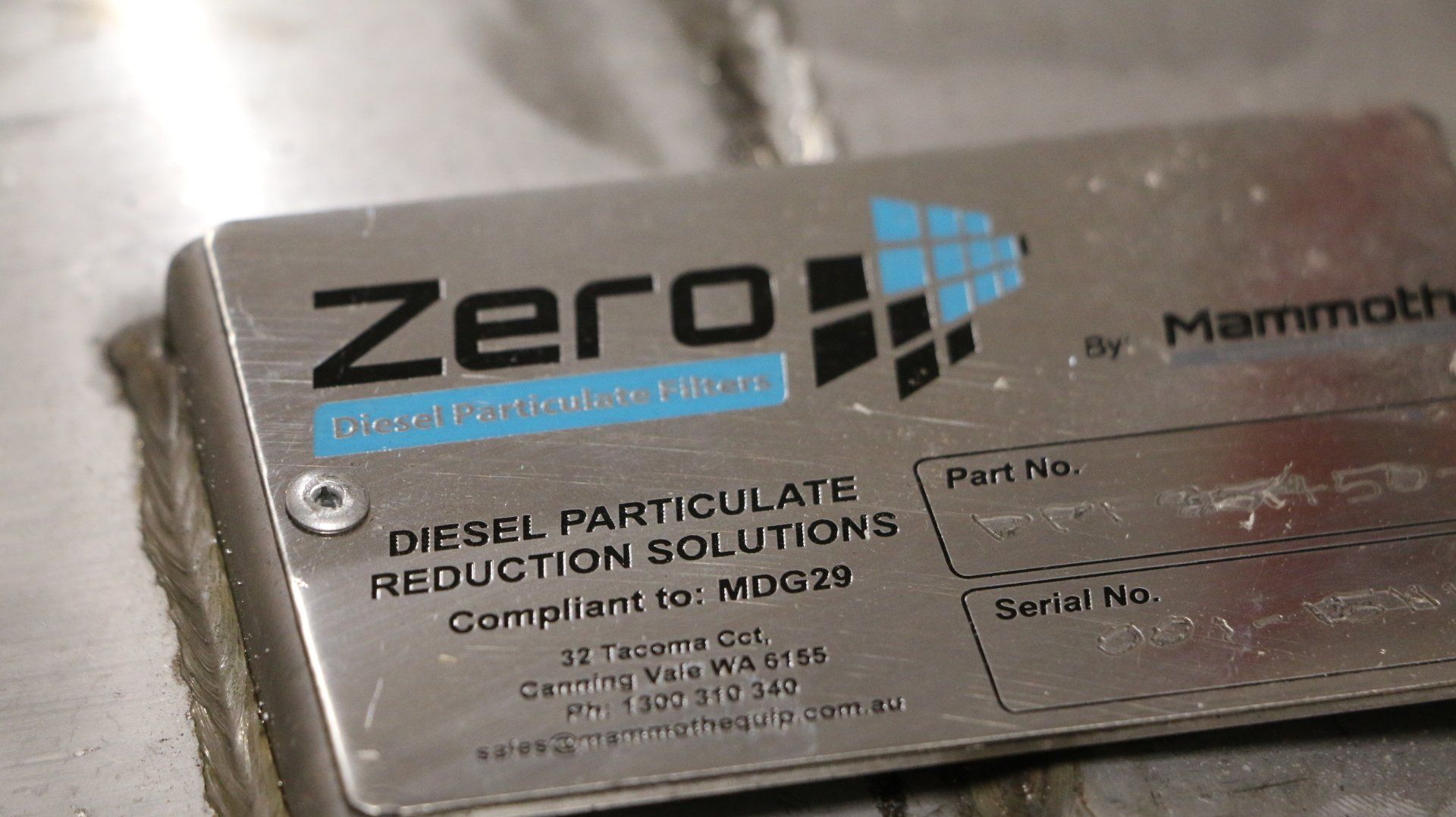

DIESEL PARTICULATE FILTERS BY MAMMOTH

ZERO - OUR RANGE OF DPF'S

Scientific studies have proven that diesel soot has a carcinogenic effect as well as being a main contributor to atmospheric smog alongside of nitrous oxide. Cleaner fuels and emission control technologies that can reduce this pollution by up to 98% are here today. We need to move to make retrofitting these highly effective emission controls to diesel engines on the road today a public health priority.

Contact Us for a free consultation and we can help you reduce your diesel emissions today!

DIESEL PARTICULATE FILTERS AT A GLANCE

NOT ALL DPF'S ARE MADE EQUALLY

Not all mine site vehicles or their diesel particulate filters are made equally.

The largest underground mining vehicles typically with heavy duty cycles are in a class of their own for their power, performance and potential emissions (depending on engine type). Our Diesel Particulate Filters are purpose built to suit OEM specifications of these vehicles.

The mid-range support vehicles are often too compact to fit a standard Diesel Particulate Filter, add to that unpredictable duty cycles and most suppliers would be waving the white flag. However our catalyzed substrate DPF has proven to be a key component in managing Diesel Particulate Emissions on these vehicles; purpose built to suit OEM specifications.

Finally the light duty vehicles, people movers, land cruisers, fuel and liquid trucks, shotcreters, etc., are often the weak-link in the chain of holistic and thorough Diesel Particulate Management. The Mammoth Sintered Metal Filters are purpose built to suit OEM specifications.

We design filters to suit individual make, model and serial variations, this considers a range of relevant factors such as; Original Equipment muffler brackets and space, engine size, power and original equipment specifications (as a function for allowable back pressure), proximity to heat sensitive components and exhaust gas flow direction.

Contact Us for a free consultation.