SOUND SUPPRESSION SYSTEMS

Mammoth is a key specialist provider of sound suppression solutions, with a reputation spanning over 20 years, partnering with mining and civil companies to meet their sound/noise emissions targets in sensitive areas – providing the best value for money solutions.

With facilities around the globe specifically dedicated to servicing the mining industry, Mammoth has the capacity to handle any request or project from small to large, with our flexible operations.

- Project management throughout

- Initial design and scope undertaken by our experienced in-house technician

- CAD Concept design and desktop evaluation – including technical analysis in a simulated environment (Computational Fluid Dynamics)

- Sourcing

- Manufacturing

- Supply

- Installation

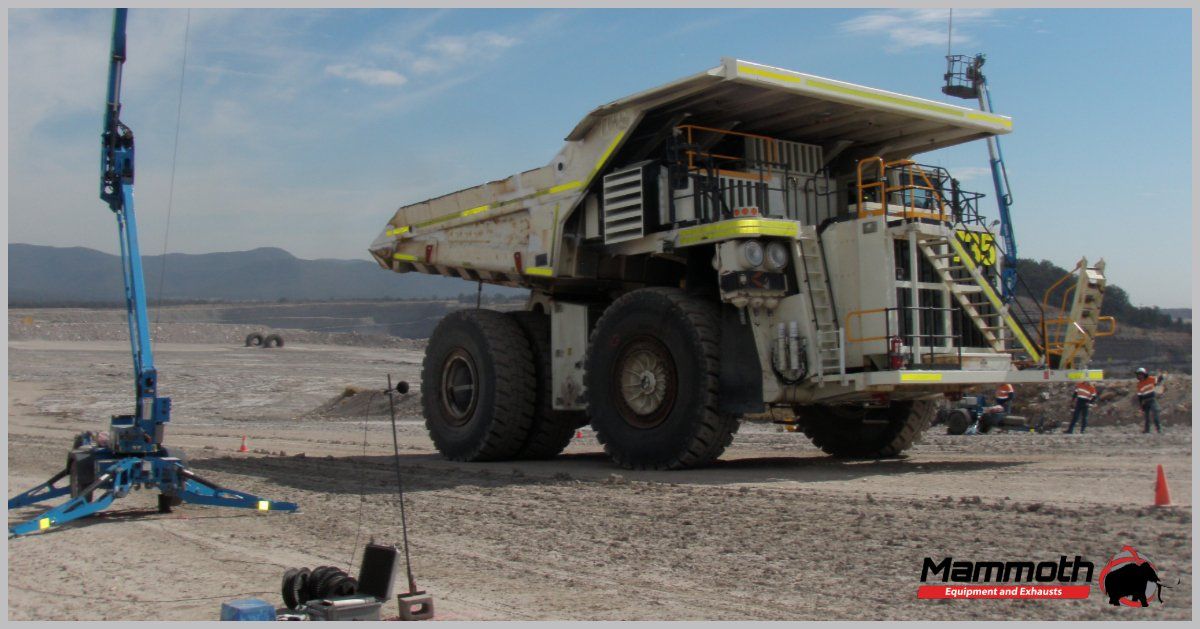

- Testing

- Maintenance friendly design with a focus on accessibility and convenience

- Sufficient cooling and mechanical requirements

- Direct fit where possible with minimal design changes to the body of the equipment

- Meet or exceed the desired sound reduction

SOUND SUPPRESSION CASE STUDY

MAMMOTH SOUND SUPPRESSION DESIGNS ARE MADE

WITH THE END USER IN MIND AND ENSURES:

- Maintenance friendly design with a focus on accessibility and convenience

- Sufficient cooling and mechanical requirements

- Direct fit where possible with minimal design changes to the body of the equipment

- Meet or exceed the desired sound reductions

“The full report has not been completed, by SVT however the prelim results below show a great reduction in sound power level to 111.9dBA and improvements over most 1/3rd octave bands

This has gone beyond the target of 113dBA which is a great result. Thanks for the support to get to this position.

So please progress as agreed the procurement and installation of acoustic treatment to the remaining 992 loaders.”

Matt Hart | Project Engineer I Capital Projects - Wagerup

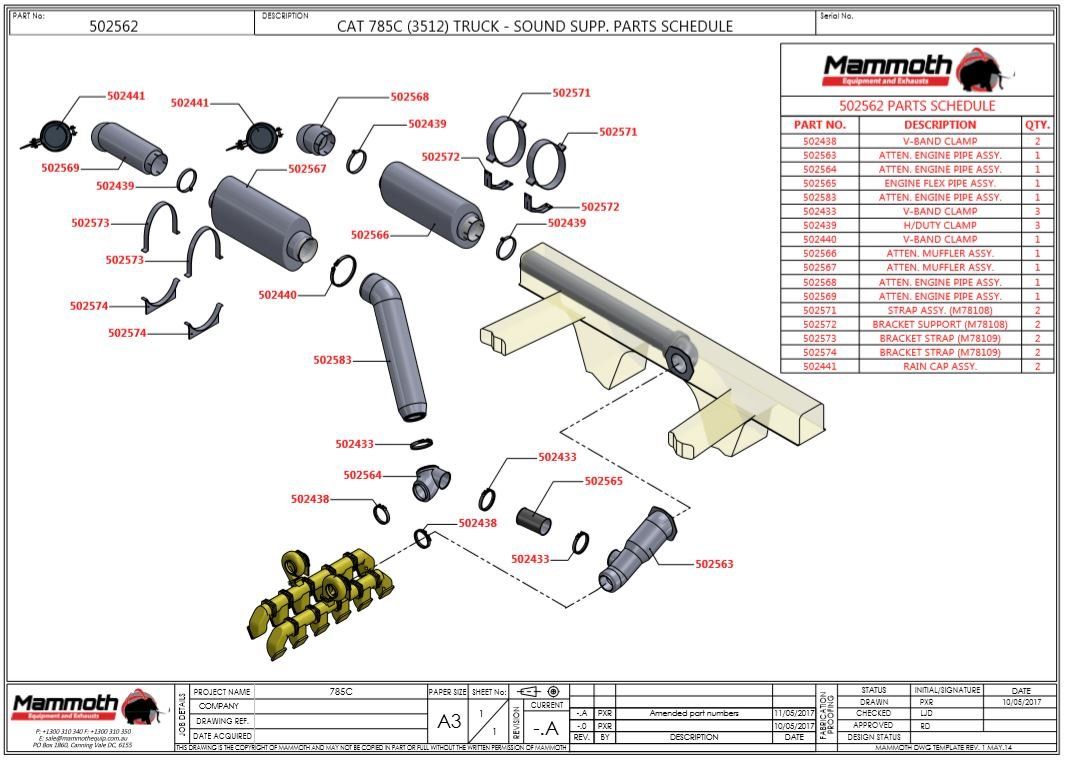

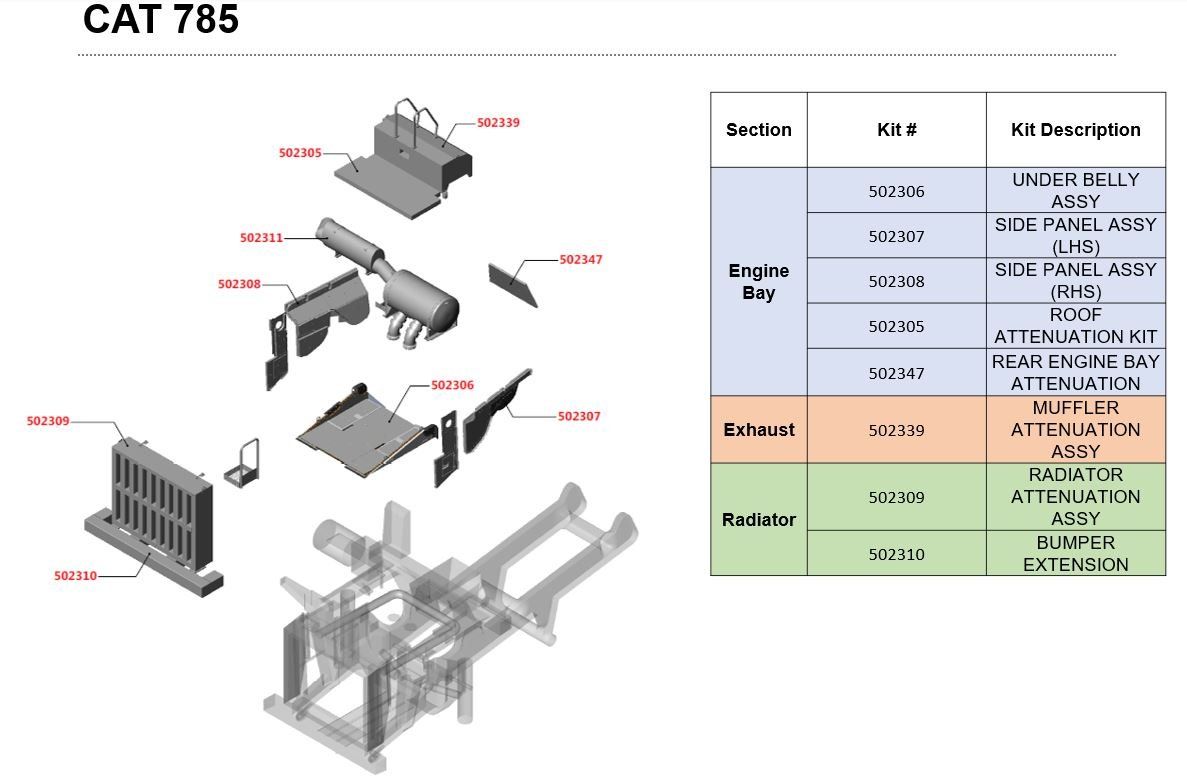

Komatsu 830E System

- Sound attenuated exhaust

- Radiator Attenuation

- Gridbox and Blower Duct attenuation (not shown)

- Enclosed Attenuated Engine Bay and Generator Panels

- Bumper / Ladder Extension and relocation