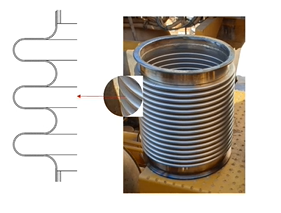

BELLOWS

High Quality | Stainless Steel | Cost-Effective | Long-Lasting | Less Downtime

Your exhaust system is only as strong as the quality of the products you use. Mammoth Equipment have designed and built corrosion-resistant, heavy-duty, multi-ply stainless steel specifically catered towards maximum life and easy fitment in mining applications. The U-shaped convolutions on the Mammoth bellows offer greater flexibility to withstand axial, lateral, and angular force which makes it more durable and less prone to fatiguing. That's why Mammoth Equipment stocks and sells high-quality exhaust flex bellows that will strengthen your overall system.

What do you use flex bellows for?

You would use flex bellows when you have vibration in multiple directions.

One example: if the engine in a 360 degree rotation independent to the mufflers mounted on the roof.

What is the difference between flex and bellows?

Flex prevents pipes cracking when you have a small amount of vibration in a single direction. Bellows are used when there is a lot of vibration in multiple directions.

The 3 most common types of bellows we work with are:

Accordion

Made up of multiple layers of very thin steel that is formed into an accordion shape. Others tend to use more layers of very thin material – easy to burn through. Mammoth have developed an accordion style flex bellows that uses thicker ply’s and is better suited for heavy duty applications.

Strip Wound

Is a continuous strip of material that is ‘S’ shaped. The strip is then interlocked as it is wound into a roll/tube.

Flex Braid

This is used often to wrap around the outside of either accordion or strip wound flex. It is designed to limit the range of motion. We have seen it rub/wear on the underneath accordion/strip wound flex and cause leaks – especially if dirt/dust gets between the braiding and the underneath flex piece.

Common issues related to current Flex Bellows:

Bellows with the 'rubberized' coating don't last long.

They leak because of heat, vibration, or dust/grit, the common components for metal fatigue and wear.

They crack due to the wrong grade of material or if the flex is too flexible, especially where the transition from the flex to the connection/flange point happens.

"Our site has completely switched over to using Mammoth 793F flex bellows, installed them 3 years ago - no issues."

- Chris (Maintenance Supervisor, North America)

The flex bellow is an important component of mobile mining equipment exhaust systems. Having a quality exhaust flex bellow as part of your exhaust system will help prevent premature failure and ultimately increases equipment uptime.

Because of the high quality and longevity of our bellows there is less equipment downtime as a whole.

This exhaust flex bellow component fails because of its:

- Design weakness

- Misalignment

- Poorly installed

Mammoth's flex bellows feature:

- Heavy-duty stainless steel

- Easy install and maintenance

- Design eliminates misalignments