complete EXHAUST SYSTEMS

Get a complete exhaust system kit or just order the few replacement exhaust parts you need.

NO MODIFICATIONS REQUIRED

FAQs

key design features

aluminized steel

Mammoth utilizes ‘aluminized steel’ when

manufacturing these components as it

combines the best characteristics of both steel

and aluminium; it offers:

- Good formability

- High temperature resistance

- Low thermal expansion coefficient

- Good corrosion resistance

PROVEN RESULTS IN MANY APPLICATIONS OF 1.5 - 2X SERVICE LIFE EXPECTANCY AND HALF THE MAINTENANCE REQUIREMENT

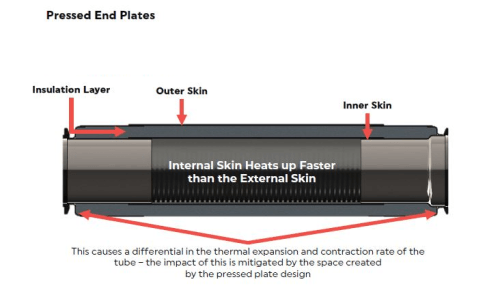

pressed end plates

Mammoth use pressed plates to allow for

expansion and contraction and mitigates

an edge fatigue stress point.

This causes a differential in the thermal expansion

and contraction rate of the tube –the impact of this

is mitigated by the space created by the pressed

plate design.

THIS IS A KNOWN ENGINEERING BEST PRACTICE

HOWEVER NOT USED BY ALL MANUFACTURERS.