Can you get more uptime with preventative maintenance for your SCR?

What does SCR stand for?

SCR, meaning Selective Catalytic Reduction, is an advanced emission control system in diesel engines to reduce the levels of harmful nitrogen oxides in exhaust gases.

SCRs are a critical component for cleaner air, better fuel efficiency, and compliance with emission standards.

How does an SCR work?

SCRs play a pivotal role in reducing harmful emissions from mining equipment.

SCR systems work through a chemical reaction that converts nitrogen oxides (NOx) and ammonia (NH3) into harmless nitrogen (N2) and water vapor (H2O).

- Injection: An aqueous urea solution, often called AdBlue or DEF (Diesel Exhaust Fluid), is injected into the exhaust stream.

- Conversion: In the SCR catalyst, ammonia (NH3) is released from the urea solution when it encounters high temperatures.

- NOx Reduction: The ammonia (NH3) reacts with nitrogen oxides (NOx) in the exhaust gases, breaking them down into nitrogen (N2) and water vapor (H2O), which are harmless components.

The result is a significant reduction in NOx emissions, which are major contributors to air pollution and smog formation.

Why preventative maintenance matters

Regular and preventative maintenance of SCR systems is vital for several reasons:

Compliance:

Many regions and industries have stringent emission regulations.

Properly maintained SCR systems ensure compliance with these regulations, avoiding costly fines and penalties.

Fuel Efficiency:

A well-maintained SCR system optimizes the combustion process, which can lead to improved fuel efficiency and cost savings.

Extended Lifespan:

Routine maintenance can extend the lifespan of SCR components, reducing the need for costly replacements.

Reliability:

Preventative maintenance reduces the risk of unexpected breakdowns or malfunctions, ensuring reliable operation.

Key Maintenance Tasks for SCR Systems

Here are some essential maintenance tasks for SCR systems:

Regular Inspections:

Periodic visual inspections of SCR components to check for damage or wear.

Urea Quality:

Ensure that high-quality urea is used, and monitor urea levels regularly.

Catalyst Cleaning:

Cleaning or replacement of the SCR catalyst if it becomes fouled or contaminated.

Sensor Calibration:

Regular calibration of sensors to ensure accurate dosing of urea.

System Diagnostics:

Utilize diagnostics tools to identify and address any issues promptly.

Contact us for a complimentary pickup, inspection and report on your SCR.

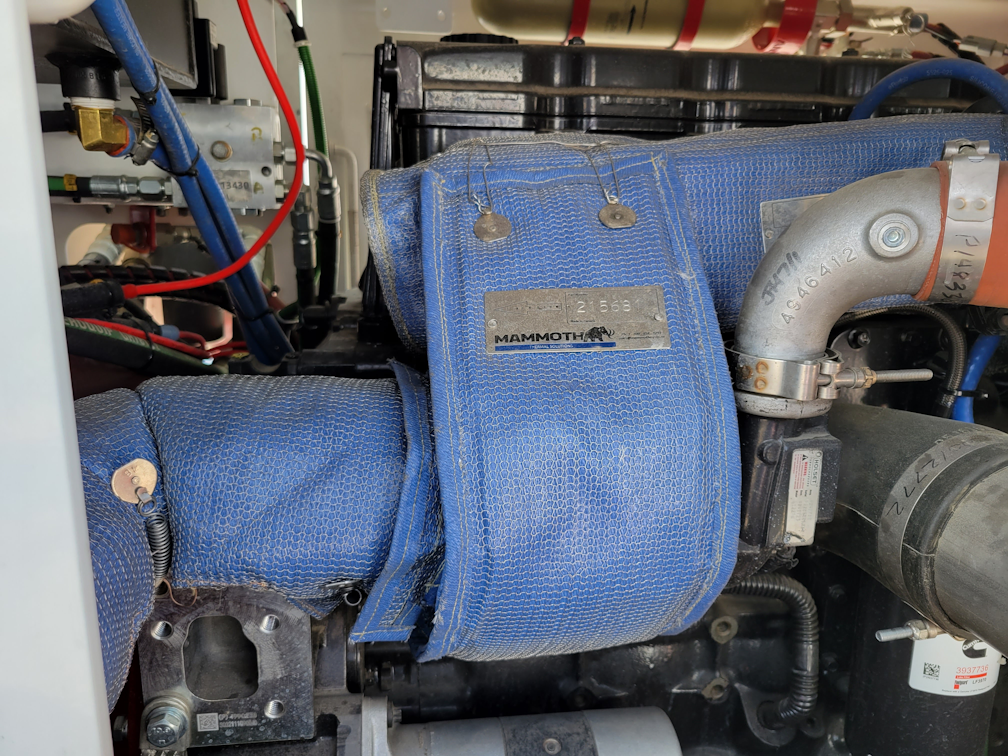

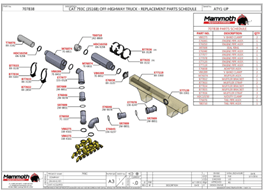

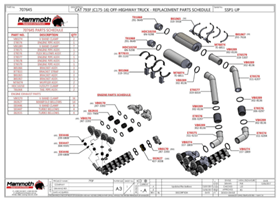

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment