Why Thermal Exhaust Blankets are a Must-Have for Mining Equipment

Protecting Your Mining Equipment with High-Quality Thermal Exhaust Blankets

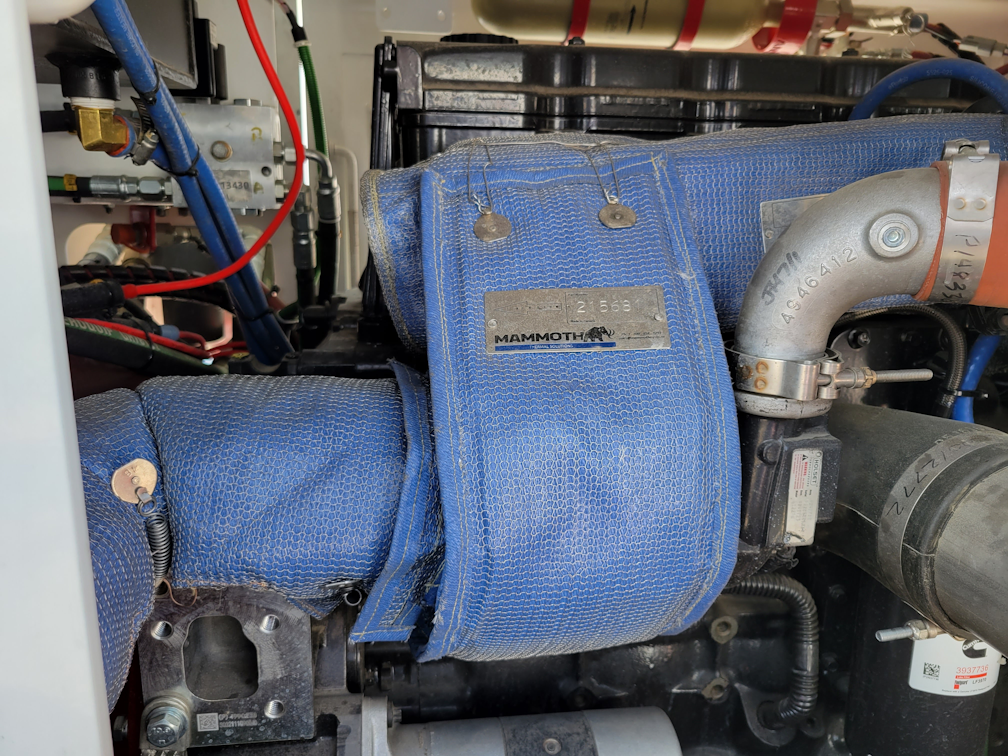

Are you looking for ways to improve worker safety and production efficiency in your mining operations? Have you considered thermal exhaust blankets? While mining machinery is essential to the global economy, it can also be dangerous for workers due to equipment working hard which results in hot components, then there is the potential of failing hoses which can spraying flammable fluids on hot exhaust. However, implementing thermal exhaust blankets can greatly reduce the risk of flammable fluids reaching hot components by acting as a barrier between the two, leading to increased safety and efficiency.

Mining equipment is prone to overheating due to long and hard haul loads. This overheating can lead to damage, component failure and unexpected equipment downtime causing financial losses. To minimize these risks, it's crucial to implement regular maintenance and inspection programs and provide employee training on safe operating procedures and emergency response. However, even with these measures in place, there is still a risk of overheating. That's where thermal exhaust blankets come in.

How to choose the right thermal blanket?

As the mining industry heavily relies on machinery, the use of insulated thermal blankets is an important part of mitigating the risks of premature or unexpected damage to equipment.

1. Predict

The use of insulated blankets significantly reduces the risk of hazards on mobile diesel mining equipment, such as burns, fires, and equipment failure and ensuring the safety of workers. To ensure the proper implementation of insulated blankets on mining equipment, it's important to assess the need for them, source high-quality blankets that meet the necessary specifications for the machinery in use, and properly install and maintain them.

2. Procure

Procurement professionals and purchasing agents play a crucial role in ensuring worker safety and avoiding costly damages in the mining industry. By properly sourcing and implementing insulated thermal blankets, they can greatly reduce the risk of hazards.

3. Protect

Thermal exhaust blankets are essential for ensuring safety in industrial and mining sectors. Properly designed thermal exhaust blankets offer several benefits, including enhanced safety for workers. Safe and high-standard thermal exhaust blankets are made of durable and heat-resistant materials like silicone-coated fiberglass and should have adequate overlap and be properly secured to prevent flammable fluids from coming in contact with hot components. When purchasing thermal blankets, it's important to evaluate them based on specific criteria like heat resistance, durability, quality of insulation materials, overlap, and ease of removal for future accessibility to ensure their safety and performance.

How Mammoth Equipment Can Serve Your Thermal Blanket Needs

We understand the importance of safety measures and equipment efficiency. That's why we specialize in exhaust blankets for mining equipment.

1. High-Quality Materials and Expertise

Mammoth Equipment's exhaust blankets are made from high-quality materials such as silicone-coated fiberglass, and our team has over 25 years of experience in the industry. This expertise ensures that our blankets are effective at reducing heat loss and preventing damage from overheating.

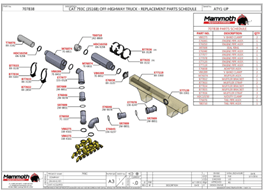

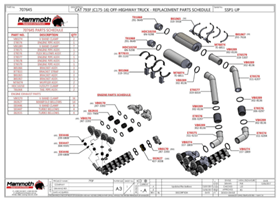

2. Custom Solutions for Your Equipment

Mammoth Equipment understands that every mining operation is unique, which is why we offer custom solutions tailored to your specific equipment. Whether you need exhaust blankets for a small or large-scale operation, our team can design and create the right solution for your needs.

3. Easy Installation and Maintenance

Installing and maintaining thermal exhaust blankets can be a daunting task, but Mammoth Equipment makes it easy. Our thermal blankets come with simple instructions and are designed for easy installation, allowing you to get back to work quickly.

Final Thoughts

The use of properly designed thermal blankets is crucial for achieving the desired outcomes of safety and efficiency in the mining industry. Procurement professionals and purchasing agents should prioritize sourcing safe and high-standard thermal blankets to ensure the safety of workers and equipment in the industrial and mining sectors. By investing in high-quality thermal blankets and ensuring proper installation and maintenance, the mining industry can achieve improved worker safety, equipment reliability and production efficiency.

Mammoth Equipment's thermal exhaust blankets are highly recommended for any mining operation that wants to prioritize safety and efficiency. With high-quality materials, custom solutions, and easy installation and maintenance, our team can help you find the right solution for your needs. Contact Mammoth Equipment today to learn more about how we can serve your thermal blanket needs.

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment