Enhancing Workplace Safety: Recent Updates to Regulation 854 on Diesel-Powered Equipment

A Deep Dive into Regulation 854: What You Need to Know for Diesel Equipment Safety

Ensuring workplace safety remains a top priority, which is why it's essential to stay up to date on the latest updates and guidelines concerning the operation of diesel-powered equipment. The recent amendments to Regulation 854 have brought about significant changes aimed at creating a safer working environment, especially in high-risk industries like mining where airborne hazards and diesel emissions are prevalent.

Exploring Airborne Hazard Management (Section 182)

The Airborne Hazard Management Program plays a vital role in maintaining workplace safety, particularly in environments where hazards like diesel emissions are common. Delve into the provided links to discover valuable insights into effective strategies and guidelines for managing airborne hazards.

Airborne Hazard Management Program

- Official Ontario Government Website – AHMP

- Research Study on Airborne Hazards in Workplace

- Guidelines for Implementation Strategies in Section 5

Navigating General Requirements for Diesel-Powered Equipment (Section 183)

Operating diesel-powered equipment requires strict adherence to comprehensive guidelines to ensure both worker safety and regulatory compliance. Explore the following links for detailed information on the general requirements for operating diesel-powered equipment, including ventilation standards for underground mines.

Comprehensive Guidelines for Operating Diesel-Powered Equipment

- Official Amendments to Regulation 854

- Ventilation Requirements for Diesel-Powered Equipment in Underground Mines

Emphasizing Airflow Considerations and Worker Safety

Effective airflow management is crucial for minimizing worker exposure to harmful emissions from diesel-powered equipment. Implementing airflow management strategies and measures to mitigate exposure are vital steps in fostering a safe and healthy work environment.

Airflow Management Strategies

- Implementation of ventilation systems for optimized air circulation

- Regular air quality monitoring

- Provision of respiratory protection equipment for workers

Measures to Mitigate Worker Exposure

- Implementation of engineering controls such as exhaust ventilation systems

- Strict enforcement of personal protective equipment (PPE) requirements

- Regular training on minimizing exposure risks

Engaging Stakeholders and Industry Experts

Collaboration with stakeholders and industry experts is pivotal in shaping regulatory amendments that prioritize safety and compliance. The revisions to Regulation 854 have been informed by valuable insights and recommendations obtained through consultations with key stakeholders and safety experts.

Collaborative Consultations for Regulatory Amendments

- Involvement of industry stakeholders, labor unions, and safety experts

- Consideration of insights from the Mining Legislative Review Committee

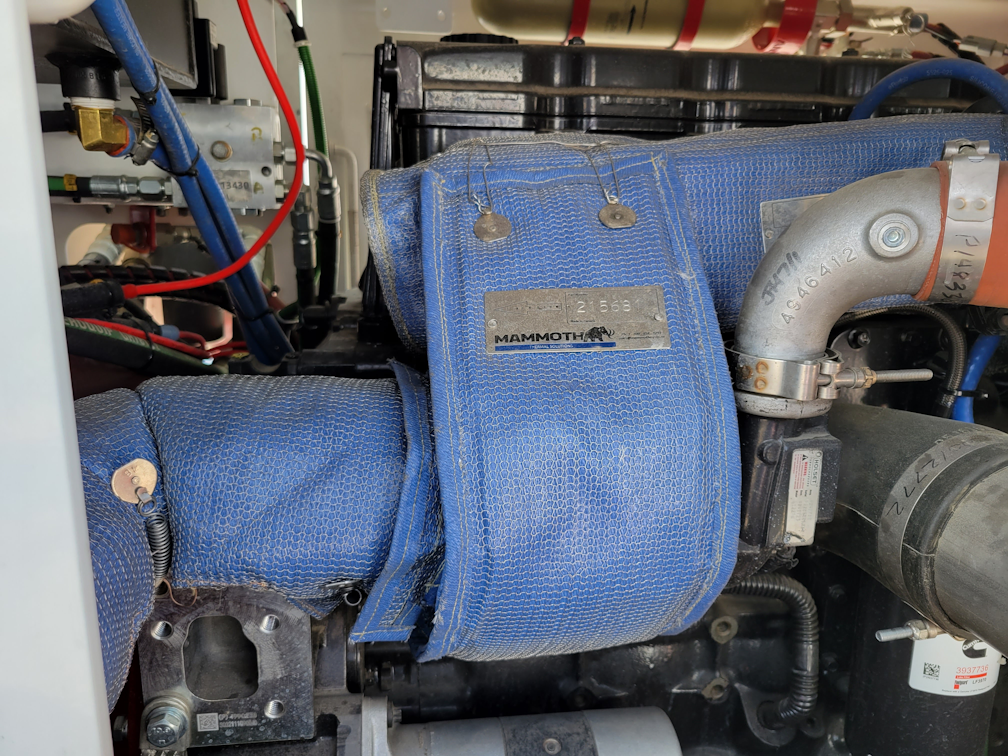

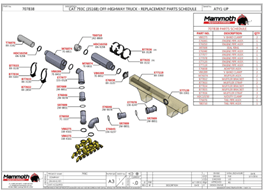

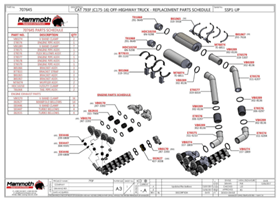

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment