Stop Fires, Reduce Thermal Incidents, Protect Your Team

The need for mining is becoming increasingly more essential in the supply of raw materials.

Mining is also one of the most perilous professions, with miners exposed to numerous risks, including fires and burns.

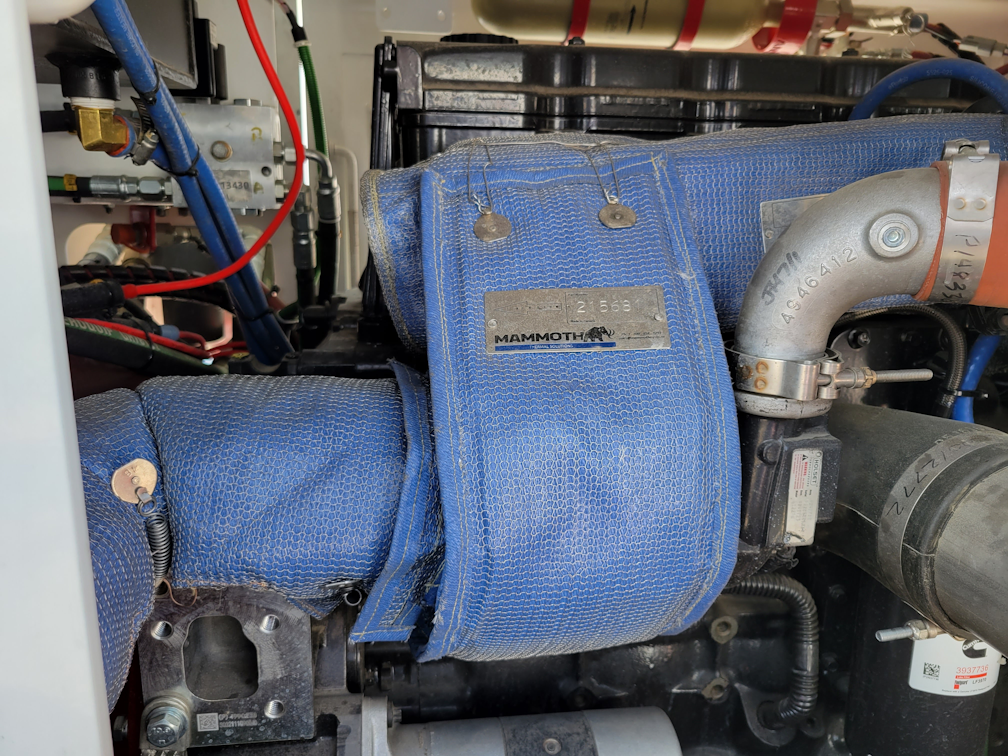

Mammoth’s thermal blankets can play a crucial role in safeguarding miners against the devastating effects of fires and thermal injuries.

Mining Risks:

Mining operations frequently occur in confined underground spaces, where ventilation is limited, and the risk of fires, explosions, and thermal injury is high.

Fires in mines can spread rapidly due to the lack of oxygen and limited escape routes.

The Role of Thermal Blankets:

Thermal blankets, also known as fire-resistant or heat-reflective blankets are supplied by manufacturers such as MacLean, KES, RDH, J&S Walden, RockTech, Normet, and Getman, are constructed from advanced materials designed to withstand extreme heat.

Mammoth thermal blankets are portable and easy to apply to various mining equipment, including boom trucks, scissor decks, transmixers, Anfo loaders, shotcrete machines, fuel trucks, and water trucks.

Reduce your fire risk and thermal incident rate:

Mining machines receive routine maintenance and repairs, so it is common for thermal blankets to be left off mining equipment after repair work is completed.

This is often because mechanics find handling the thermal blankets uncomfortable and itchy, as well as hard to install.

Operating heavy mining equipment without thermal blankets is a risk because hose leaks can cause fires when flammable fluids meet hot exhaust.

Reduce the fire risk at your mine site by implementing a double check for thermal blankets after routine maintenance work.

You can get support from Mammoth Equipment to manage your fire risks with

- Easy-apply and remove Mammoth blankets

- Onsite training for installing thermal blankets

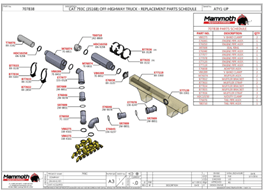

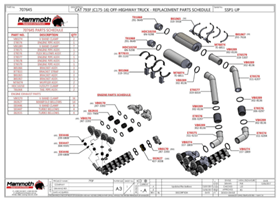

- A custom fit blanket kit specific for your equipment model and engine

- Overlapping blankets (like shingles on a roof) to prevent any gaps and hot spot exposures on your equipment

Some visual differences between regular and Mammoth blankets:

Learn more about how blankets can help your team.

Mammoth Equipment training sessions

Educate mechanics on the value of thermal blankets, making installation easier

Include a fleet assessment to identify your safe machines and those needing improvements

Leave you with diagrams of equipment issues showing hot spots on a current machine setup

Contact us today to schedule your complimentary assessment.

Start a chat with us in the bottom right-hand corner.

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment