Causes of Equipment Fires and How to Mitigate Them

Surface Sales • February 18, 2021

How to Mitigate the Causes of Equipment Fires

Fire eruptions related to heavy-duty mobile mining equipment can cause severe destruction for industrial companies, costing them millions of dollars each year.

Even a light spark in mining fields can be enough to provoke an explosion that not only puts the expensive equipment but also your workers at risk. That’s why it is important to realize the primary causes of equipment fires so you can take the necessary preventive measures to mitigate them beforehand.

In this article, we’ve put together a list of issues that typically contribute to mining equipment fires. We’ve also discussed the ultimate solution to keep these causes at bay. So, you can have peace of mind and a secure working place for your employees while saving money on equipment repairs and downtime.

Common Causes of Equipment Fires

1. Flammable Fluids

Equipment fires caused due to flammable and hot liquids can result in severe and fast spreading fires. The mining equipment already works at a significantly high temperature, which means you can’t afford to let any flammable fluid get in touch with any of your working equipment.

2. Hot Components

The components on heavy duty mining equipment are often extremely hot because of the continuous work of moving loads over numerous hours. These hot components coupled with the hot or flammable fluids are often the primary cause of fire explosions.

3. Faulty Equipment

Faulty machinery or weak lines is another one of the likely causes of equipment fires. Any mechanical device can become a fire hazard when there’s friction between moving parts that are already damaged.

4. Leaking Lines

Leaking pipes or hydraulic lines and hot surface equipment can be another cause of fire break outs.

5. Electrical Hazards

Lastly, electrical fires caused due to exposed wiring, overloaded outlets, or static discharge can be enough to put the working crew and your heavy-duty mining equipment at risk. It can be especially damaging when an electric spark comes in contact with a flammable liquid.

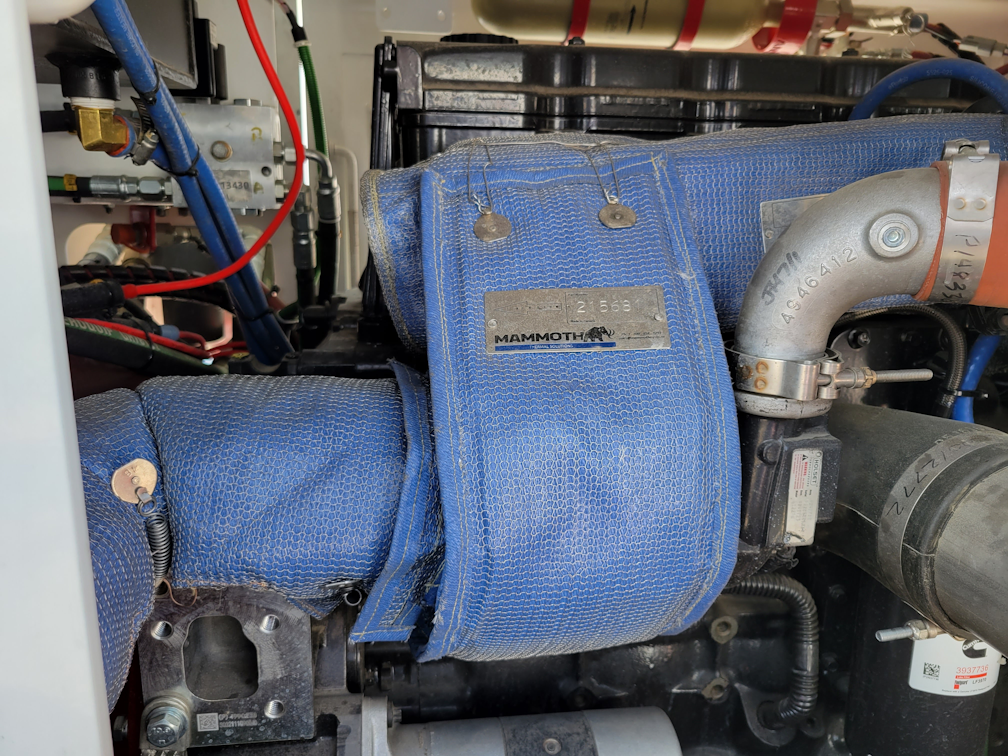

Thermal Exhaust Blankets For Preventing Fires

We suggest installing Mammoth thermal exhaust blankets for mitigating equipment fires. It’s a very practical and cost-effective solution for the top five fire causes mentioned in the previous section. These thermal blankets are capable of withstanding high temperatures over 1200˚c

Moreover, the absorption-proof material used during its manufacturing and the additional overlap provided with the blankets ensures there is no gaps on the blanket seams and that your hot components are full covered and diminishes the chances of your equipment catching fire if there’s a leaking line.

Do you require more information regarding Mammoth thermal exhaust blankets and their installation process? If so, please feel free to contact us through our website

or call us at 800.854.8291!

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment

The Komatsu 830 haul truck has an impressive payload capacity, and excels in efficiently transporting substantial volumes of minerals over challenging terrains. Prioritizing safety, the Komatsu 830 incorporates advanced braking systems and stability controls, creating a secure working environment for operators. Extensively used in large-scale mining operations, the Komatsu 830 proves indispensable for optimizing logistics, streamlining workflows, and meeting production targets. One of the challenges with the Komatsu 830 is Selective Catalytic Reducto r ( SCR ) clogging or crystalizing.

What does SCR stand for? SCR, meaning Selective Catalytic Reduction, is an advanced emission control system in diesel engines to reduce the levels of harmful nitrogen oxides in exhaust gases. SCRs are a critical component for cleaner air, better fuel efficiency, and compliance with emission standards.

The need for mining is becoming increasingly more essential in the supply of raw materials. Mining is also one of the most perilous professions, with miners exposed to numerous risks, including fires and burns. Mammoth’s thermal blankets can play a crucial role in safeguarding miners against the devastating effects of fires and thermal injuries. Mining Risks: Mining operations frequently occur in confined underground spaces, where ventilation is limited, and the risk of fires, explosions, and thermal injury is high. Fires in mines can spread rapidly due to the lack of oxygen and limited escape routes. The Role of Thermal Blankets: Thermal blankets , also known as fire-resistant or heat-reflective blankets are supplied by manufacturers such as MacLean, KES, RDH, J&S Walden, RockTech, Normet, and Getman, are constructed from advanced materials designed to withstand extreme heat. Mammoth thermal blankets are portable and easy to apply to various mining equipment, including boom trucks, scissor decks, transmixers, Anfo loaders, shotcrete machines, fuel trucks, and water trucks. Reduce your fire risk and thermal incident rate: Mining machines receive routine maintenance and repairs, so it is common for thermal blankets to be left off mining equipment after repair work is completed. This is often because mechanics find handling the thermal blankets uncomfortable and itchy , as well as hard to install. Operating heavy mining equipment without thermal blankets is a risk because hose leaks can cause fires when flammable fluids meet hot exhaust . Reduce the fire risk at your mine site by implementing a double check for thermal blankets after routine maintenance work. You can get support from Mammoth Equipment to manage your fire risks with Easy-apply and remove Mammoth blankets Onsite training for installing thermal blankets A custom fit blanket kit specific for your equipment model and engine Overlapping blankets (like shingles on a roof) to prevent any gaps and hot spot exposures on your equipment Some visual differences between regular and Mammoth blankets:

Whether you are a heavy equipment fitter, a mobile maintenance mechanic or a mobile maintenance superintendent , you know the work and time that goes into keeping the heavy diesel mobile equipment operational at your site. Maintenance can be planned or unexpected and involves many different projects, some of which are listed below: Haul Truck Rebuilds Preventative Maintenance Engine Changes Does your site have engine changes or complete rebuilds scheduled soon? Here is one thing our customers have been asking for:

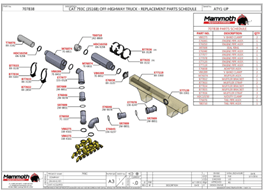

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793C haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 156-6237 2W-9078 156-6247 8X-3361 8X-3360 8X-3135 7C-3337 155-0528 242-8869 8X-3142 Mufflers 7E-6811 Brackets 8X-3130 8X-5103 8X-2850 8X-3128 8X-3132 Clamps 1W-4161 2W-8851 7E-8452 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

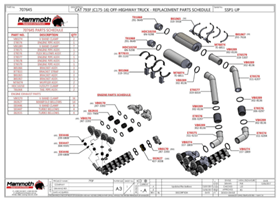

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793F haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the C175-16 engine. This includes: Pipes 311-6213 311-6204 319-6019 311-6207 319-5307 291-9649 Flex Bellows 306-0297 Mufflers 7E-6811 Brackets 319-5918 293-7616 8X-3130 319-5912 Clamps 302-8136 337-1809 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.

Mammoth recognizes the impact of having equipment down on mining operations. The CAT 793D haul truck is a common machine found on many sites globally. As a result of discussion with many site mobile maintenance teams, Mammoth has reverse engineered the exhaust kit for this haul truck with the 3516B engine. This includes: Pipes 250-6082 250-6083 250-6084 250-6085 242=8869 8X-3142 Flex Bellows 242-0799 Mufflers 7E-6811 Brackets 8X-3130 242-0792 242-0783 Clamps 302-8136 1W-4161 6N-9298 Improvements made by the Mammoth engineering team have proved to extend component life and increase equipment uptime . Some of the improvements made include upgraded flanges, heavy gauge steel pipe with fitted blanket kit available and enhanced exhaust flex bellows . All components are a direct fit replacement to the OEM factory supplied components for easy, simple and quick installation. Components stocked at multiple warehouse locations across North America.