Passive Regeneration Diesel Particulate Filters

Designed for hard rock mines and base metal mines

Learn how DPF regeneration works

An excellent example of the overall performance of Mammoth’s Passive Regeneration DPFs was on a hard rock mine in Northern Ontario. The site ran a fleet of CAT AD30 haul trucks in varies haulage cycles. Mammoth installed a DPF system for a 200-hour trail run.

The trial results showed

that the back-pressure remained below the alert level. Other significant benefits included:

• Reduced DPM (particulate) levels by 98% at the tailpipe

• Reduced CO by 90% • Reduced NO2 by 17%

• Did not cause any significant increase in NOx levels

• Eliminates downtime

• Easy install lightweight solution

The underground operators on this site said that “the system allowed for cleaner air, greater visibility and working conditions.”

Learn about other products lines that we have with similar benefits

Still not sure? Did you know we offer no obligation trials on our products?

Trial a product for a specified period of time - if you don't like it, return it - no questions asked.

Request a trial today!

Contact Ralph Deayton, our Underground Mining Specialist at 800.854.8291

Dual Wall Exhaust for Mobile Mining Equipment

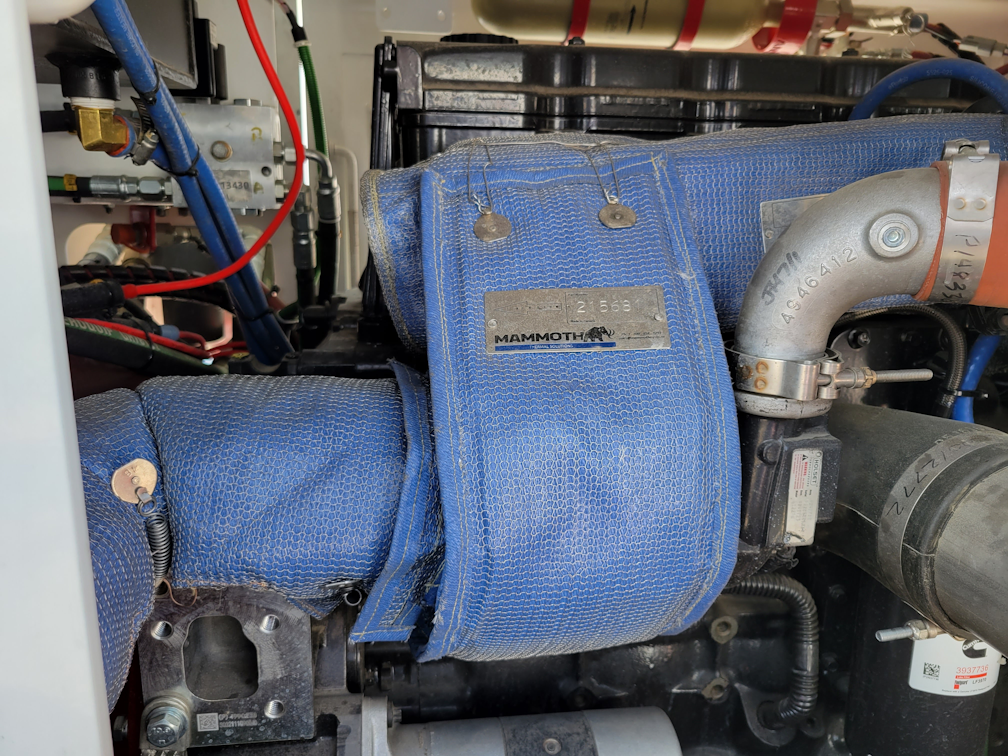

Thermal Exhaust Blankets for Mobile Mining Equipment

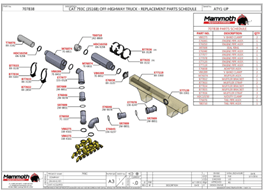

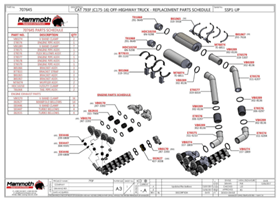

Alternative to OEM - Replacement Exhaust Products for Mobile Mining Equipment

Air Precleaners for Mobile Mining Equipment

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment