Exhaust Flex Bellow Replacements That Last

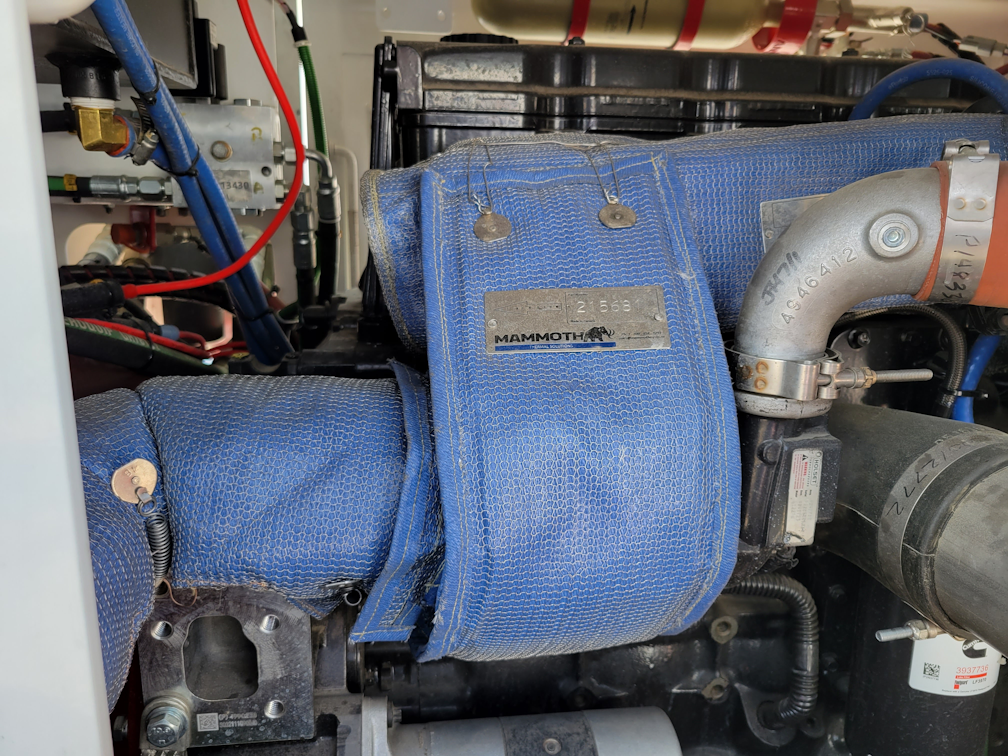

Replacement Exhaust Flex Bellows

The flex bellow is an important component of mobile mining equipment exhaust systems. Having a quality exhaust flex bellow as part of your exhaust system will help prevent premature failure and ultimately increases equipment uptime.

These are some common complaints we hear about flex bellows:

- They are expensive

- The ones with the 'rubberized' coating don't last long

- They leak – combination of heat, vibration, dust/grit – ideal components for metal fatigue and wear

- They are cracking – if the wrong grade of material or if the flex is too flexible, metal fatigue can develop and cracks can form especially where the transition from the flex to the connection/flange point happens

If you're looking to strengthen the exhaust system and prevent equipment downtime, consider using replacement exhaust flex bellows from Mammoth Equipment.

This is feedback we have been getting on flex bellows we have provided to our clients:

- Engineered for extended life. These ones are lasting 2 – 3 years where previously they were only lasting 12 months

- Direct fit replacement to OEM, no modification required

- 30-40% less expensive than OEM

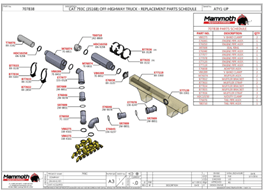

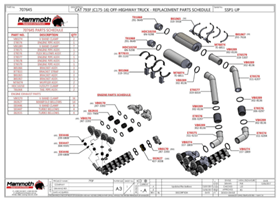

The 3 most common kinds of bellows that we work with are:

Accordion

- Made up of multiple layers of very thin steel that is formed into an accordion shape. Other tend to use more layers of very thin material – easy to burn through. Mammoth have developed an accordion style flex bellows that uses thicker ply’s and is better suited for heavy duty applications.

Strip wound

- Is a continuous strip of material that is ‘S’ shaped. The strip is then interlocked as it is wound into a roll/tube.

Flex braid

- This is used often to wrap/go around the outside of either accordion or strip wound flex. It is designed to limit the range of motion. We have seen it rub/wear on the underneath accordion/strip wound flex and cause leaks – especially if dirt/dust gets between the braiding and the underneath flex piece.

Stainless Steel Construction

Instead of rubberized coatings, Mammoth Equipment's exhaust flex bellows are made with multi-ply stainless steel.

Cost-Effective

We manufacture our products in North America and are able to offer our customers significant savings as compared to others. Our replacements are a retrofit solution that has been reverse-engineered and had customer-requested improvements made to the quality and life span of the product.

Long-Lasting

One of the biggest problems with exhaust flex bellows is being able to stand up to the conditions and environments that they are used in with mining equipment. Our bellows have been designed with this in mind and are made with strong, durable materials that allow a longer life span.

This has been verified by our customers – “Mammoth bellows have been on our 797B truck in the oil sands for almost two years and are in perfect condition”. Another customer is on their fourth month with the Mammoth bellows and has been thoroughly impressed because their old system lasted three months on average.

Another customer has now completely switched over to Mammoth bellows because they have experienced no issues with them despite them being installed three years ago.

Contact us here to get started.

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment