FreezeGard prevents heavy equipment from freezing up!

Prevent equipment freeze up with Mammoth’s FreezeGard

Winter is approaching quickly, bringing with it cold weather snaps that are particularly harsh on industrial machinery. These severe conditions often lead to mechanical damage and breakdowns resulting in lengthy and costly downtime, reduced productivity and needless expenses to fix your equipment.

Companies can easily rack up Hundreds of Thousands of Dollars in expenses during a winter season if no corrective measure is taken.

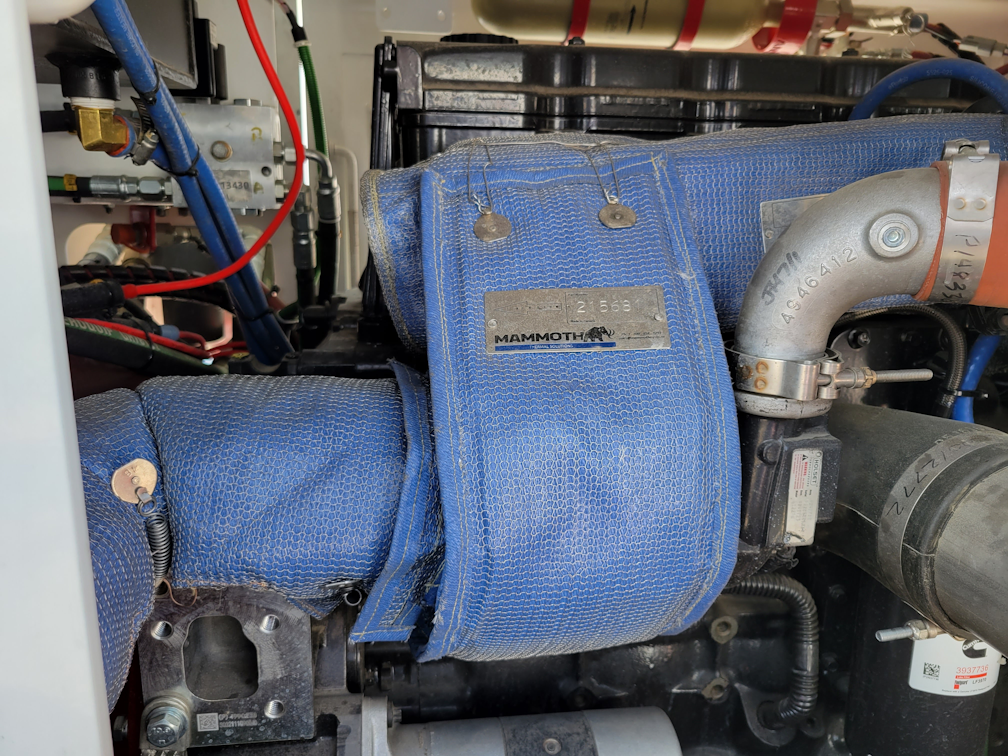

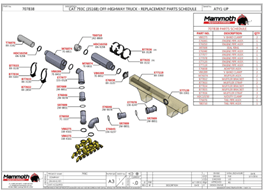

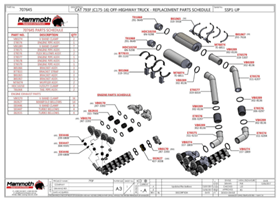

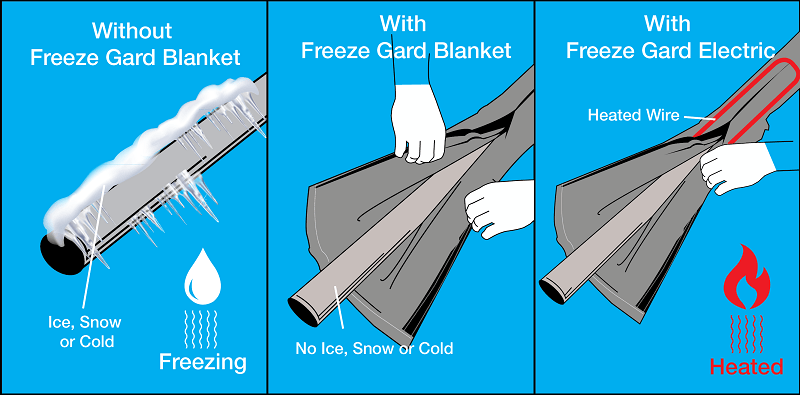

Mammoth Equipment & Exhausts is particularly adept at helping your machinery operate normally in extremely cold conditions, with a proven record of reducing downtime caused by frozen fluids, tanks and lines in machinery using our proprietary FreezeGard insulation blankets with a Heat Trace Wire option. FreezeGard reduces equipment downtime by preventing freeze ups on pipes, hoses, tanks and much more. It maintains the temperature of critical components above freezing and ensures a broader temperature operating window for your machinery in harsh weather conditions. FreezeGard is easy to remove and install, lasts for a long time and can be adapted to specific customer/equipment requirements. It is suitable for Tier 4 engines, Water Lines, Grease Kegs, DEF Tanks, Valves, Flanges, Conveyer Belts, Control Panels and other temperature sensitive equipment.

FreezeGard blankets are waterproof, ultraviolet protected and retain flexibility across a broad temperature window ranging from -50C to +50C. They are made of a durable silicone cloth that doesn’t break down or crumble over time, and are designed for use with an optional Heat Trace Wire that warms the required area sufficiently and enables the blanket to retain the heat where it is needed. The Heat Trace Wire is customizable to fit a variety of voltage options (12 Volt, 24 Volt, 120 Volt, 240 Volt). It is designed to be attached to the FreezeGard blankets either by straps, which are very flexible and easy install in most applications, or by means of a Black Heavy Duty Tubing best suited for DEF or any other box or tank-like applications. The heavy duty tubing provides extra protection against wearing down to the bare wire.

Numerous Mining Sites across North America rely on FreezeGard to successfully mitigate unforgiving weather conditions during the winter. For example, a Mammoth customer installed FreezeGard blankets on the water lines of its rotary drills. Before installing FreezeGard blankets, it had about 10-15 freeze ups each winter season, resulting in numerous days of downtime along with the ensuing repair bills. After installing Mammoth FreezeGard blankets, freeze ups diminished to just 1-2 per winter season, freeing up enormous company resources and leading to higher revenue.

Major advantages of FreezeGard:

Reduced Downtime: Prevents equipment from costly freeze ups in extremely cold conditions

Cost Effective: In less than one season, you will get a complete return on your investment

Easy to Install: No special tools required

Removable & Reusable: Blanket kits are easy to remove and reuse

Custom Kits: Custom blanket kits are available for any equipment

Winter is a Few Weeks Away

Order your FreezeGard Today

Exhaust, Blankets & Intake Systems for Diesel Mining Equipment